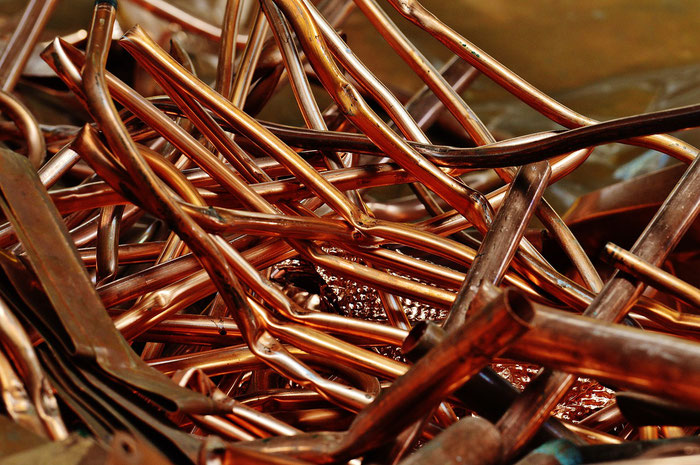

copper tube manufacturing

The production process of copper tubes starts with the extrusion of a rough 600 kg preheated copper block with a diameter of approximately 30 cm. The press pushes the copper through an extrusion die to a tube with about 3.5 mm wall thickness.

The extrusion die is usually made out of a hot work tool steel.

Changing from steel to zirconia extrusion die inserts is increasing life time and surface quality of the tube significantly.